What Are the Regulations for the Use of Recycled Plastic?

The recycling industry is a complex environment with a myriad of different regulations being updated every few years so it isn’t particularly easy to keep up with it. In addition to this, these regulations vary in each country, region, and sometimes even localities.

Today, we want to shed light on the world of rules and laws regarding the plastic recycling industry with a specific focus on the current regulations in force in the USA, Europe and India for packaging and food-packaging made with recycled resins. So, if you want to know more, read on!

WHO INFLUENCES THE PLASTIC INDUSTRY?

The process of how plastics are regulated, used, managed and finally discarded is influenced by many factors such as:

Consumers and NGOs that pressure manufacturers, retailers and companies to disclose information about the products they buy (this includes clarity on the procurement of materials, suggestions on the use of the product and on its disposal, etc.).

Political pressure and government regulations at different stages of the plastic value chain.

Businesses with their differing supply chain strategies.

In addition, local councils play an important role in developing recycling and education programs on the issue.

Manufacturers often are the most affected groups when it comes to plastic regulations since most policies developed throughout the years have focused on plastic packaging. Producers are increasingly asked to consider the life cycle of their products to find ways to minimize the impact these will have on the environment. A good viable option for them is to use recycled plastic rather than virgin in the production process.

WHY IS PLASTIC RECYCLING SO REGULATED?

Since the 1970s, glass, steel, aluminum, and paper have been recycled for food-contact use. Post-consumer use contamination has not been a major concern with these materials. Aluminum beverage containers contain on average 70% of recycled material[i], the highest percentage of recycled content amongst all types of beverage containers. Glass containers, on the other hand, are recycled up to 74% of the time in the EU.

These materials are so fit for recycling because they do not degrade by normal use and are more resistant to contamination. Plastic, however, presents a few more issues. Because this material can include up to 4000 different chemicals inside of it[ii], it requires different and stricter forms of regulations for its re-use.

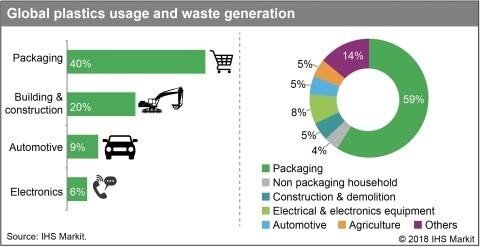

The largest sector which utilizes plastic today is industrial packaging[iii]. This is why the world’s major economies, the United States, the European Union and other countries have set as a priority the development of guidelines to ensure that products made with recycled plastic are fit for usage in packaging and food packaging.

Global plastics usage and waste generation. (Source: IHS Markit)

United States

In the US, manufacturers of articles made from recycled plastic are responsible for ensuring that the recycled material is of suitable purity for its intended use and will meet all the existing specifications for the use of virgin plastic. These requirements are contained in the Code of Federal Regulations Title 21 and suggestions for the use of recycled plastic in product packaging are contained in the Guidance for Industry - Use of Recycled Plastics in Food Packaging.

The Food and Drugs Administration’s main concern about the use of recycled plastic is that contaminants from used plastic may appear in the final product. For this reason, the FDA is available to evaluate each proposal of potential use of recycled plastic one by one.

During the evaluation, the Federal agency includes personal suggestions as to whether the proposed recycling process will produce pure plastic suitable for food-contact application or not.

Because of the above-mentioned related risks, manufacturers who want to use recycled plastic for their food packaging and be certified by the FDA, should present information regarding:

The complete recycling process including a) description of the source of PCR to make sure only plastic that complies with regulations is recycled. b) description of the steps taken to ensure the recyclable plastic does not come in contact with contaminants.

Tests to show that all potential contaminants are removed during the recycling process.

A description of the future use of the plastic obtained from the process including the type of food that will be in contact with the material, duration of the contact, and the intended temperature of use.

European Union

The European Union is leading the way to develop a comprehensive circular strategy to include plastic waste back into the economy. It aims to create additional values by generating business opportunities and providing environmental and societal benefits. As a part of the transition from a linear economy, the EU revealed its strategy on plastics in the document “A European Strategy for Plastics in a Circular Economy”[iv]. To achieve its ambitious goal of all plastic packaging to be either reusable or recyclable by 2030, the old continent is working to improve the economics and quality of plastic recycling.

Regulations of recycled plastic for food-contact applications are included in Regulation No 282/2008. In addition, products manufactured using recycled plastic material must meet the requirements of Plastics Regulation 10/2011.

Under Regulation No 282/2008 “only food-contact materials and articles that contain recycled plastic obtained from an authorized recycling process may be marketed in the EU after petitions for recycling processes are evaluated”. Once a petition is received, the European Food Safety Authority (EFSA) issues an opinion on the safety of the process, then the European Commission will decide whether or not to accept the recycling process.

Along with this, Plastics Regulation 10/2011 sets out specific requirements for the manufacture and marketing within the European Union of plastic materials and articles intended to come into contact with food. Among others, these requirements specify that only the substances included in the Union list of authorized substances can be used in the manufacture of plastic layers.

Evolution of the recycling rate of plastic packaging waste in the EU (Source: Eurostat)

India

India is one of the largest consumers of plastics products. The Central Pollution Control board estimates that approximately 26,000 tons of plastic waste are created every day. It is also one of the most affected countries by the problem of plastic pollution because a lot of this plastic waste goes uncollected and eventually ends up untreated in the environment.

Regulations regarding plastic, PET and recycled PET usage in India are issued by the Bureau of Indian Standards. The document IS 14534: 1998 titled “Guidelines For Recycling of Plastics” indicates the step-by-step procedures for the recovery and recycling of plastic waste. It explains in detail the procedures to follow for the selection, segregation and processing of waste/scrap that are suitable for recycling.

In addition, the guideline lists the suggested end-product appropriate usages of recycled plastic as it follows: Non-food containers for detergents, shampoos, reusable packaging containers, etc. One year later, in 1999 the Recycled Plastics Manufacture and Usage Rules were introduced prohibiting the usage of recycled plastic in producing bags, sacks or wrapping used in food packaging, adding that food shall be packed only in virgin plastic.

FINAL CONSIDERATIONS

The US, Europe and India have all adopted different approaches when dealing with recycled plastic. In the US, as long as the recycled plastic presents the same quality required for virgin plastic, it can be included in packaging and food-contact wraps without the need for approval (even though that is recommended). Europe, on the other hand, is adopting a much stricter line by reviewing each recycling process step-by-step. Also, in the European Union, countries have to comply with standards that exist at three levels: National, European, and International. Finally, India is not ready yet to trust the usage of recycled plastic in food-contact products but encourages other applications.

The efforts to increase plastic recycling rates not only involve governments but should include citizens, businesses and standards-setting agencies. A much-discussed, essential tool that can help accelerate the transition to a circular plastic economy are recycling certifications. These can help provide clarity and transparency in the recycling processes and, in addition, they assure manufacturers that the raw materials they are acquiring meet their requirements and are truly recycled.

At Plastics For Change, our recycling processes have been certified by the European Food Safety Authority (EFSA) and we have achieved the Nestle A Grade Standard for beverage bottles, as well as REACH compliance. This means that our plastic is not only suitable for food-contact use but has maximum levels of purity.

If you want to know more about our recycled plastic, click here.

References:

[i] https://www.aluminum.org/product-markets/aluminum-cans#:~:text=Aluminum%20cans%20contain%20on%20average,than%20competing%20beverage%20container%20types.

[ii] https://interestingengineering.com/it-takes-more-than-4000-chemicals-to-make-plastic-packaging-new-research-finds

[iii] https://advances.sciencemag.org/content/3/7/e1700782/tab-figures-data

[iv] https://ec.europa.eu/environment/circular-economy/pdf/plastics-strategy-brochure.pdf